Product Description

The edge banding machine, is used to band the straight and curved panel edges for custom furniture production.Woodworking edgebanding machines are divided into manual edgebanding machines and automatic edgebanding machines designed for stores and companies looking for efficient and precise edgebanding services and solutions.

The functions of automatic edgebanding machines include pre-milling, gluing, sealing, end cutting, rough and fine trimming, corner rounding, scraping and polishing. Manual edgebanding machines and semi-automatic edgebanding machines are also available for straight and curved cabinet edgebanding.

Edge sealing tape can be made of various materials, such as PVC, ABS, melamine and wood veneer. It can paste PVC edgebanding tape from 0.4 to 3mm to plywood, MDF, birch, walnut, maple and other wood panels in panel furniture and whole house furniture production.

We offer a full range of fully automatic edgebanding equipment for mass production and inexpensive edgebanding machines for small stores. Contact us for the latest strapping machine quotation.

JINAN SUDIAO CNC ROUTER CO., LTD.

12 Years of Experience Professional Trustful CNC Router Manufacturer in China. Over 20,000 Machines Sold Worldwide. 24*7 Service, 12 Months Warranty, Lifetime Support. Contact SUDIAO for High Performance and Reliable CNC Router at Bargain Prices. JINAN SUDIAO CNC Router Company Is Found In 2007 .As A Professional CNC Router Manufacturer SUDIAO Is Constantly Devoted in R&D and Manufacturing of Different Cabinet Kitchen Solutions Such As CNC Panel Production Line S6 , Smart CNC Nesting Machine S2/S3/S5 ,Five-Side Drilling Machine, Laser Model Side Drilling Machine, Assembled Solid Doors Process Center and Wood CNC Process Center . We Now Establish Several Branches and Agencies in 18 Countries Like USA UK France,Germany Canada.,etcWe Has Imported Advanced International Technology and Production Process. Developing High Performance ,High Quality Machines to Meet the Different Customers Requirement is our Ceaseless Pursuit and Development Direction .

Product Parameters

Product Detail

Product functional features.

Pre-milling: the use of double milling knives to retouch the corrugated marks, burrs or non-vertical phenomena caused by the processing of the cutting and opening saws, in order to achieve a better edge sealing effect. This allows the edgebanding to fit more closely to the board, with better integrity and aesthetics.

Glued edging: Through a special structure, the edging sheet and the edging material are evenly glued on both sides to ensure a more solid bond.

Flush: Through precise linear guide movement, automatic die tracking and high-frequency high-speed motor fast cutting structure is adopted to ensure the cutting surface is flat and smooth.

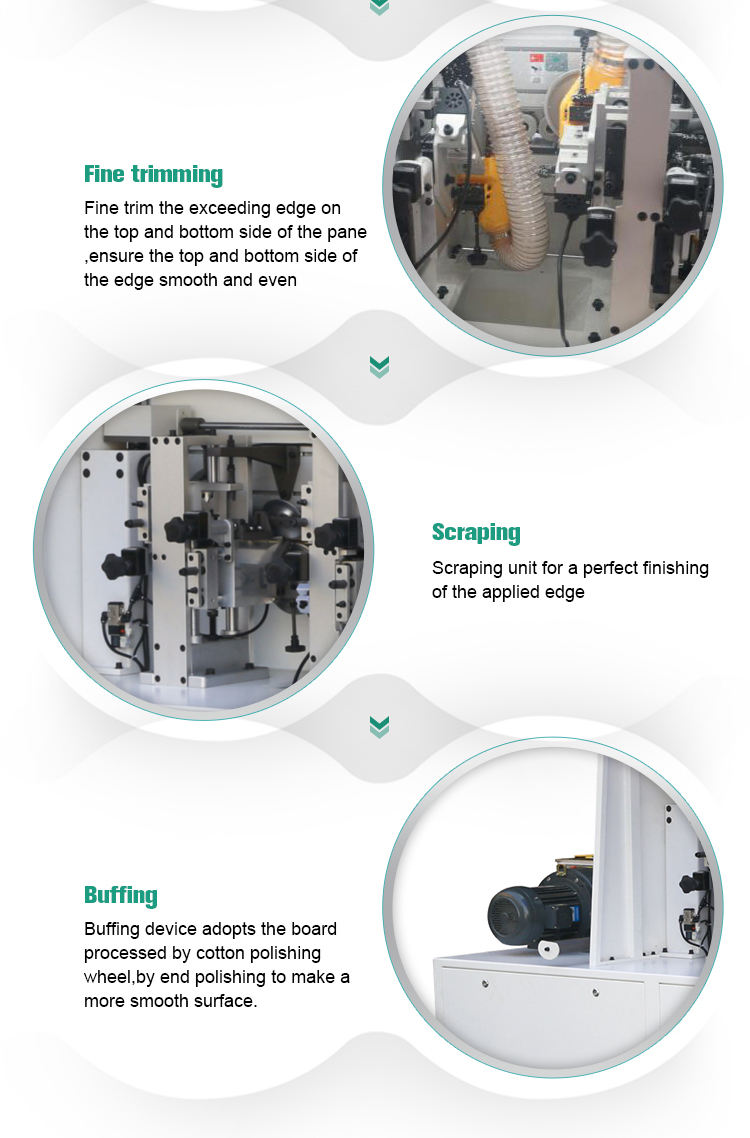

Fine trimming: all adopt automatic tracking against the die and high-frequency high-speed motor structure to ensure that the upper and lower parts of the trimmed sheet are flat and smooth. It is used to trim off the excess sealing material on the top and bottom of the trimming strip of the processed sheet.

Scraping: used to eliminate the ripple marks caused by the cutting process of non-linear movement of the trimming, making the upper and lower parts of the sheet smoother and neater.

Polishing: cleaning the processed sheet with a cotton polishing wheel to make the edging end surfaces smoother by polishing.

Edge banding machine Application

The automatic linear edge banding machine is suitable for such plates: MDF, block board, solid wood board, particleboard, polymer door plates, plywood etc.

Workshop

Exhibition

Edge Banding Machine Buyer Guide

What is the Edge Banding Machine?

The edge banding machine is a kind of woodworking machine dedicated for cabinet edge banding. It plays the role of edgebanding in the processing process of the furniture production line. Compared with the traditional manual banding process, the sealing line of the edge bander has the advantages of being straight, delicate, and smooth.

Common classification of edge banding machines

According to the degree of automation, the edge banding machine mainly includes the manual edge bander, semi automatic edge banding machine, and automatic edge banding machine. They can achieve different functions and have distinct banding effects.

The main difference between fully automatic and semi-automatic lies in the processing functions. Semi-automatic edge banders can realize such functions as gluing, edge banding, upper and lower trimming, and polishing. But the fully automatic edge banding machine has the functions of pre-milling, gluing, edge banding, trimming, contour tracking, scraping, polishing, and so on. The automatic edge bander machine has gradually replaced the semi-auto type due to its high cost-performance ratio.

From the shape of the edge banding, the banding machine can be divided into the straight edge banding machine, straight and curved edge banding machine, and bevel edge bander machine.

Function introduction of edge banding machines

Most automatic industrial edge banding machines on the current market can realize basic 5 functions. These functions include gluing and banding, end cutting, trimming, scraping, and polishing.

How much does an edge banding machine cost?

The edge banding machine price varies greatly for different machine models. Besides, the functions, specifications, and manufacturers also have an effect on banding machine price.

Generally speaking, the automatic edge banding machine price is far higher than that of the manual models. The automatic edge banding machine price ranges from $10,000 to $30,000. While the manual edge bander may only cost about $400 to $3,000.

In addition, the more functions an automatic edgebander has, the higher the edge banding machine price. For example, the price of an E-60 banding edge machine is about $12,000. An E-70 automatic edge banding machine costs you about $14,000. The E-70JDS edgebander for sale may cost about $23,000.

What’s more, other specifications, selection of parts and components, after-sales service and other factors also affect the edge banding machine cost.

Applications of industrial edge banding machines

The wood edge banding machine is mainly used for edge banding of medium-density fiberboard, wood board, solid wood board, particleboard, high-gloss board, plywood, etc. That’s the reason why the edge bander is also called the plywood edge banding machine, melamine edge banding machine, MDF edge banding machine, etc.

In terms of wood materials, it can complete birch edge banding, maple edge banding, walnut edge banding, and other wood veneer edge banding work.

The fully automatic edge banding machine has extensive use in middle and large-sized furniture making factories. It has such advantages as stable operation, high automation level, reliable performance, and affordable price. Furthermore, the automatic edge bander machine is an indispensable CNC machine in many furniture production lines.

The manual edge banding machine is good at banding both straight and irregular edges. It is the best edge banding machine for small shops. Besides, it is possible to move the manual edge bander machine from one workplace to another for on-site banding operation.

How to operate an edge banding machine?

Although the automatic edge banding tape machine has a high level of automation, operators still need to pay attention to some matters during operation. The following steps describe the general operating procedures of an automatic CNC edgebander.

How to ensure the good gluing quality of edge banding machines?

In simple terms, the banding process is to stick the banding tape to the side surfaces of a wooden board with glue. So, the essential part of an edge banding operation is the gluing process. It should be uniform and continuous so that the edge banding tape can be fully glued to the board surfaces. Then how to ensure good gluing quality? What factors can affect the gluing effect? The following descriptions may give you some hints.