Product Description

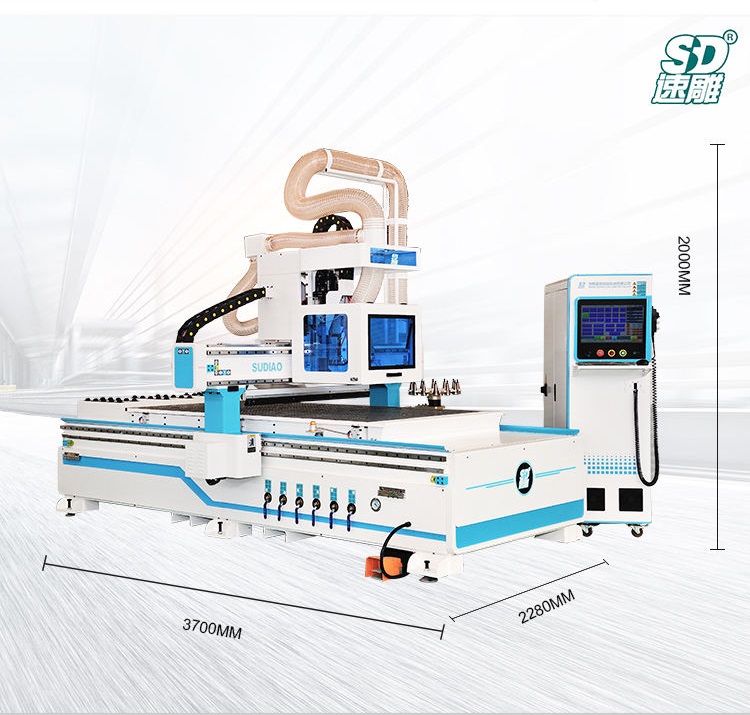

Product Parameters

Product Display

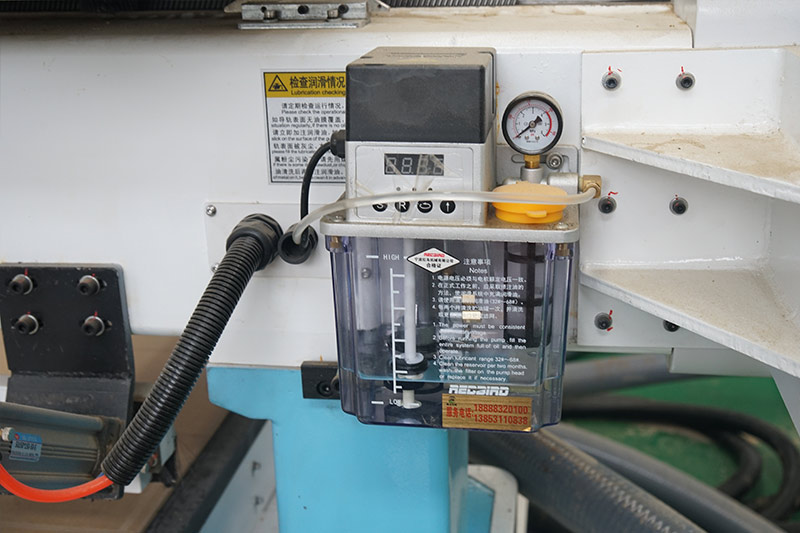

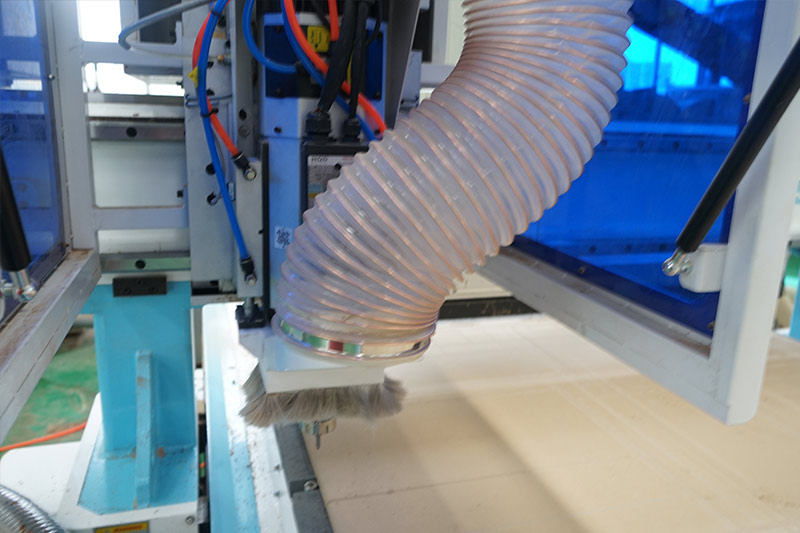

Product Detail

Product functional features.

1、Function: automatic punching, automatic slotting, automatic opening, automatic pushing, automatic engraving.

2, 9KW automatic tool change spindle with 11KW four-way frequency conversion matching, with 12 knives disc servo motor tool change library infinitely change, than the stepping tool library tool change time shortened at least three seconds.

3、5 + 4 vertical drill realises fast punching function, automatic switching during processing, fast speed and high precision.

4、YASKAWA servo with Xinbao reducer, high torque, to ensure the processing speed and stability of the equipment.

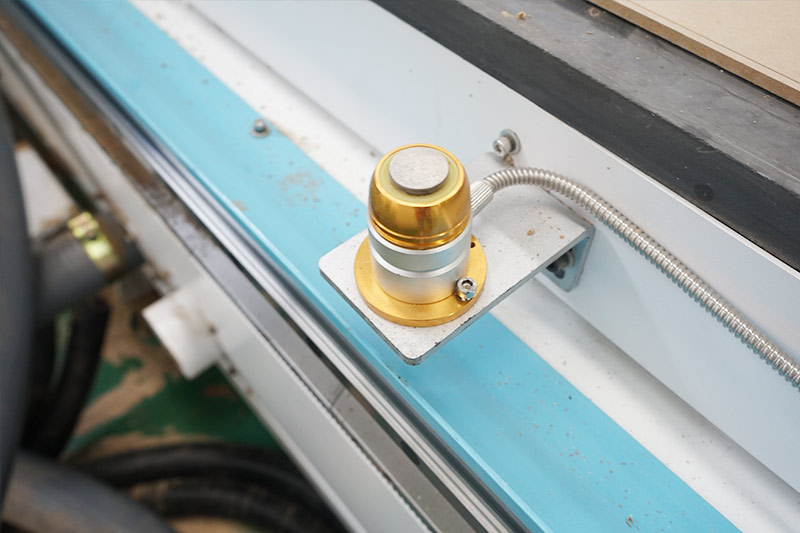

5、Yintai 30 square rail: relatively large specifications, large contact surface, strong load-bearing capacity, which can better ensure operational stability during high-speed processing.

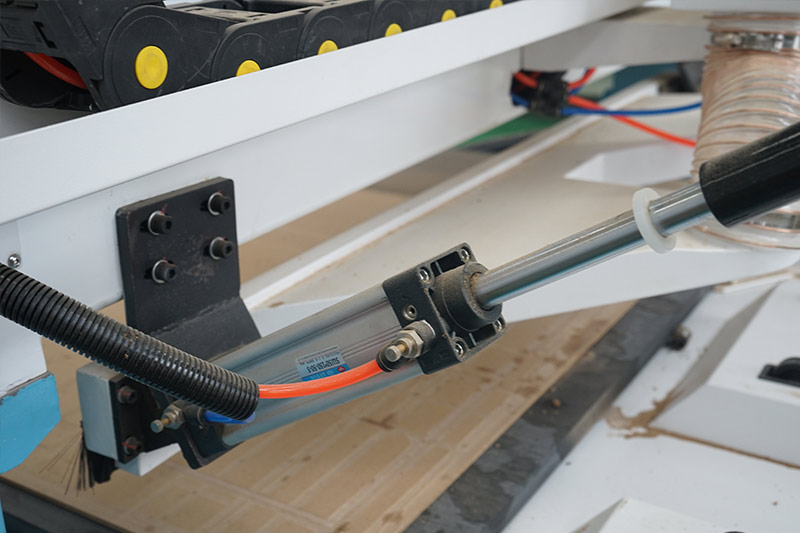

6、The equipment is equipped with automatic material pushing function as standard, which can realize the plate pushing to the working table in the front section of the equipment after the processing is finished, and has the function of secondary dust removal

7, the bed must be vibration aging, tempering treatment, large CNC machining centre milling mounting surface, to ensure the stability and accuracy of the equipment.

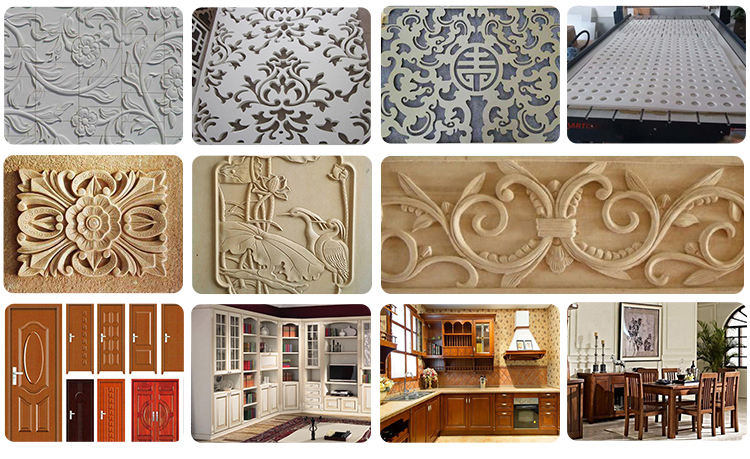

Product Application

1.Woodworking Industry: MDF, wood, acrylic, PVC, double-color board, brass, aluminum, marble, crystal.

2. Advertising industry: advertising billboard, sign making, acrylic cutting, graphic mold forming and processing of many kinds of advertising terms.

3. Architectural model industry: metal models of copper, aluminum, iron etc, and non-metal models, such as artificial marble, grave, plastic board, PVC, board etc.

4. Other industry: image engraving, embossing, craft and gift industryy.