In the field of furniture manufacturing, punching equipment has always been one of the key tools. As a kind of high-efficiency and high-precision punching equipment, 6 sides cnc drilling machine adopts advanced numerical control technology, which can realize automation and intelligent operation, and is gradually emerging in the field of furniture production.

Positive influence of 6 sides cnc drilling machine on panel furniture industry:

1. Improve efficiency and reduce costs

Compared with the traditional manual drilling equipment, 6 sides cnc drilling machine can realize automatic continuous work and greatly improve the production efficiency. At the same time, it can automatically identify the processing files and automatically complete the processing process according to the preset processing scheme, reducing manual intervention and labor costs.

2. Stable precision

The 6 sides cnc drilling machine adopts intelligent sensors and control system, which can ensure the accuracy of the position and size of each hole. At the same time, it is equipped with an air-bearing worktable and an air-bearing platen, which form an air layer on the upper and lower surfaces of the plate during processing, which has good stability and avoids processing errors caused by vibration.

3. Promote industrial upgrading

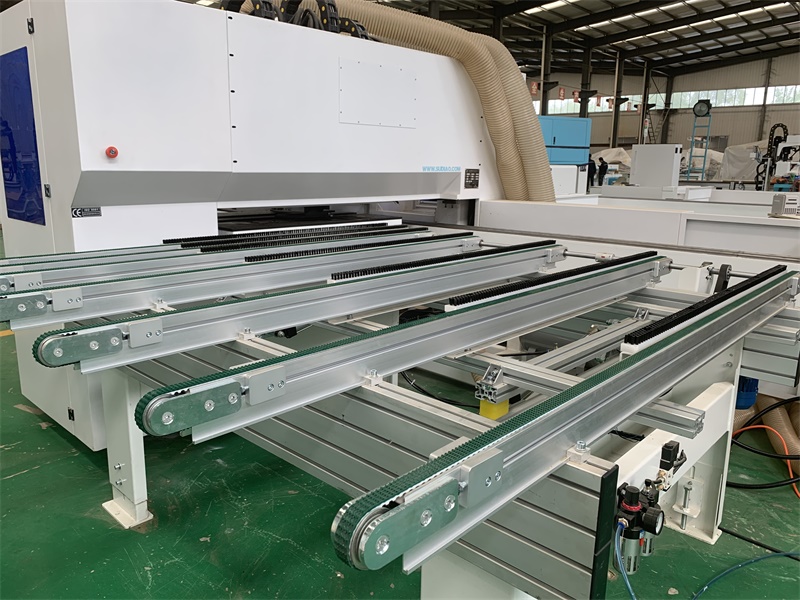

The 6 sides cnc drilling machine can be flexibly used with CNC router, automatic edge banding machine and other equipment to form a fast, accurate and automatic panel furniture production line, which is helpful to optimize the production technology of enterprises, improve processing efficiency, promote industrial upgrading and meet the automatic production mode of furniture manufacturers.

6 sides cnc drilling machine not only improves the production efficiency and punching accuracy of panel furniture industry, but also reduces the production cost and operation difficulty, and it is becoming one of the indispensable equipment in furniture production industry.