Many enterprises in the whole house customization industry are increasingly inclined to provide customers with multi-directional services through design, processing and installation, which can not only save costs and improve profits, but also control product quality in the whole process. Therefore, more and more manufacturers begin to have their own Furniture Customization factories, and the panel furniture cnc machine is one of the important equipment.

As the name suggests, the panel furniture cnc machine is to complete all the processes of plate loading, cutting, punching, blanking, polishing, edge banding, film coating and so on in one automatic production line, so as to greatly reduce the high cost, high waste and low efficiency brought by manual processing and production.

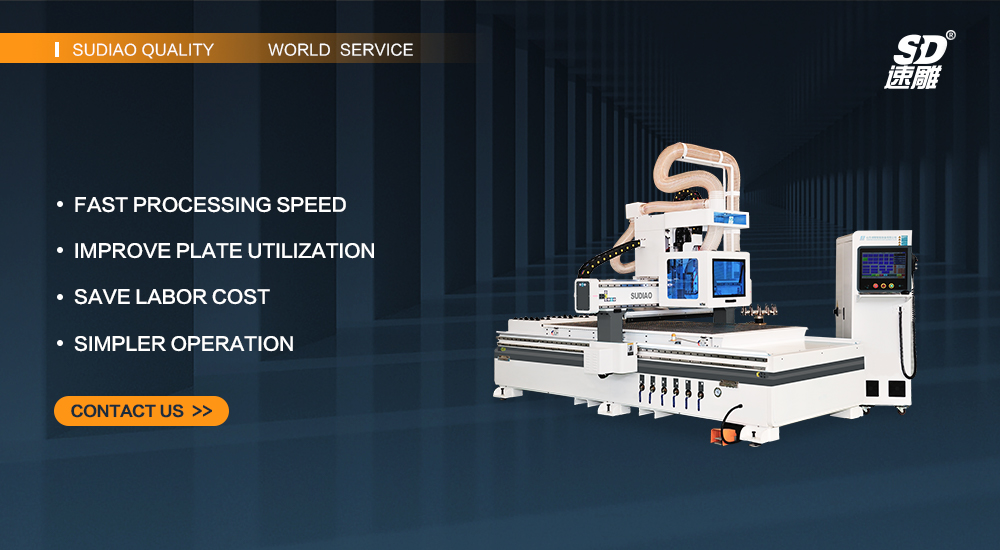

Advantages of using panel furniture cnc machine in the whole house customization industry:

- Fast processing speed

The panel furniture cnc machine can continuously process plates, and its processing speed is incomparable to that of the traditional sliding table saw. In addition, the pipeline operation saves the interval time to a great extent, and realizes the seamless connection between the processing processes. - Improve plate utilization

At present, the furniture design in panel furniture cnc machine is completed by computer. Through the analysis of furniture design data and the optimization of typesetting software, the raw materials of plates can be processed reasonably, so that the utilization rate of plates can be greatly improved. - Save labor cost

The panel furniture cnc machine can realize the automatic loading and unloading of plates, and the cutting and edge sealing can be completely automated through a production line. One worker can complete the processing of the whole production line. However, traditional sliding table saws and other equipment require the cooperation of at least two or more workers. - Simpler operation

The panel furniture cnc machine can completely realize fool operation. The manufacturer only needs 2-3 days of training to make the operator fully master the operation method. - Meet environmental protection requirements

Dust will not be generated in the whole processing process, and the dust absorption device equipped with it can absorb the generated dust to a large extent. However, traditional processing equipment such as sliding table saw will produce a lot of dust, which not only pollutes the environment, but also causes great harm to human body.

Therefore, no matter from which perspective, panel furniture cnc machines have incomparable advantages over traditional sliding table saws and other processing equipment. In addition, its processing effect and accuracy are also much higher than that of manual equipment. Therefore, manufacturers in the whole house customization industry are increasingly inclined to use panel furniture cnc machines.